No products in the cart.

Air Operated, Cooling, Fan Clutch, Heavy Truck

Compare

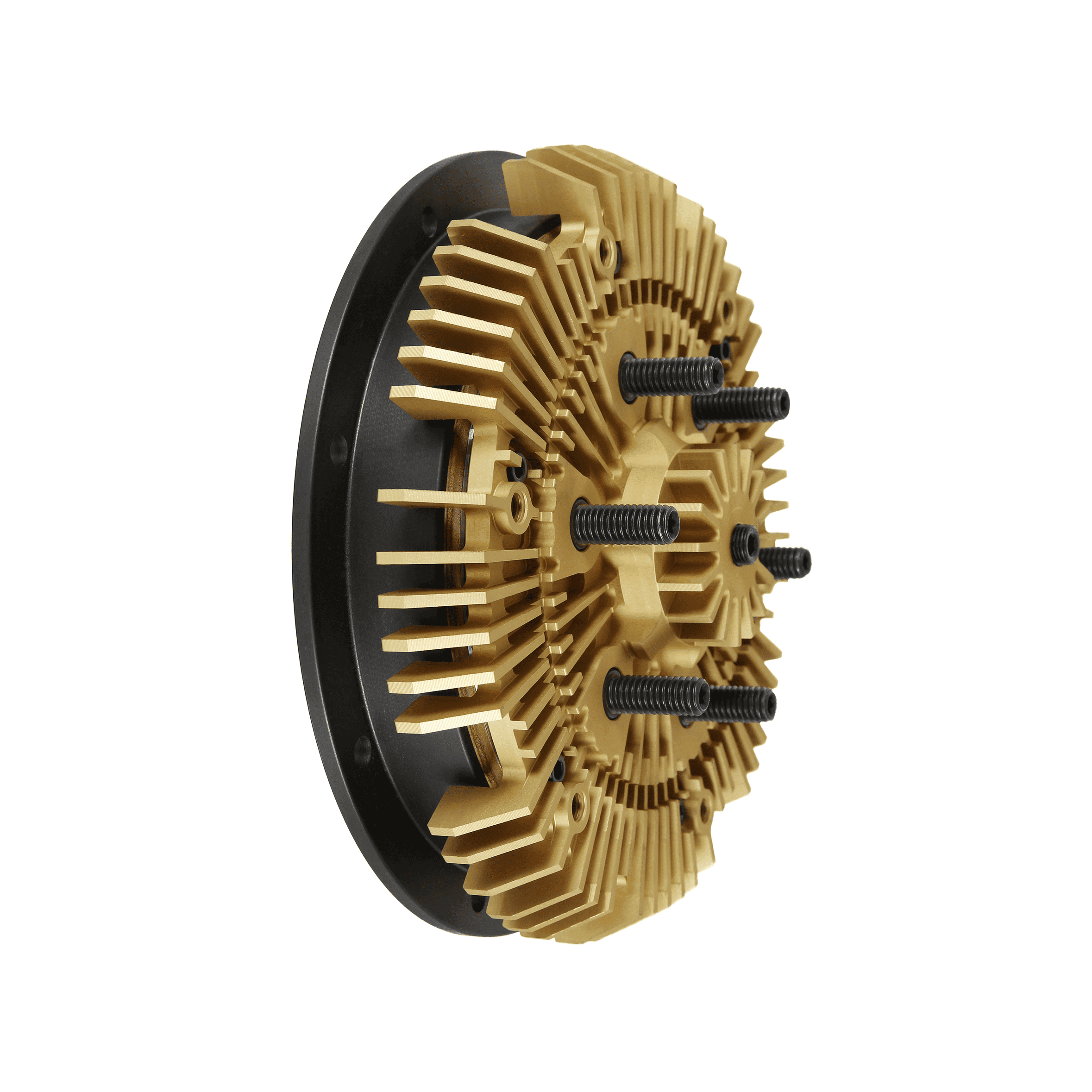

24-256 Kit Masters 2-Speed Gold Top Fan Clutch Rebuild Kit for 2.56” pilot with 2 Pulley Bearings

Availability:

2 in stock (can be backordered)

2-Speed version of the 14-256.

$872.40 Each

2 in stock (can be backordered)

24-256 Kit Masters 2-Speed Gold Top Fan Clutch Rebuild Kit for 2.56” pilot with 2 Pulley Bearings

24-256 Kit Masters 2-Speed Gold Top Fan Clutch Rebuild Kit for 2.56” pilot with 2 Pulley Bearings

Upgrade while replacing your worn Horton Drivemaster fan clutch! Kit Masters patented Gold Top Rebuild Kits reduce nine components into one component assembly, saving significant installation time and reducing the risk of installation errors.

One Kit Fits All

When you purchase a 2-Speed GoldTop®, you receive everything you need in one easy to install kit. Compare that to the competitors, who require you to choose between many different kits along with an assortment of separate bearing kits. Our one kit replaces nearly every one of theirs. Having everything in one box ensures that every wearable component will be replaced and your fan clutch will be rebuilt properly the first time!

Highest Torque Rating

With over 5,000 inch-pounds of torque, the 2-Speed GoldTop® will handle nearly all fan blades! Less Time To Install Our exclusive design combines nine separate components into ONE FINAL ASSEMBLY – this dramatically reduces installation time and installation errors. The 2-Speed GoldTop® installs exactly like our original GoldTop on/off rebuild kit, making it easy for everyone.

Higher Quality Internal Components

- Kevlar impregnated friction material

- Cast on cast construction reduces corrosion and wear

- Elimination of one seal equals one less leak path

- 4-point urethane seal

Fail-Safe Design

- Innovative design that will AUTOMATICALLY LOCK UP fan clutches when the friction material nears the end of its life.

- Lower Cost

- Upgrading your fan clutch is as simple as installing the 2-Speed GoldTop® Kit.

- Lower cost vs. new • Lower cost vs. re-manufactured

- Less failures • Less time to install

- Multiple Fan Pilot Configurations

By building the 2-Speed GoldTop® with an interchangeable fan pilot system, it can handle both 2.56” and 5” fan pilots. No need for separate kits! Guaranteed Fit. The 2-Speed GoldTop® is built with size in mind. Since it’s no larger than your original spring-engaged fan clutch, it will fit any application and any fan blade. OEM competitors can’t even claim that!

Why Use a 2-Speed Fan Clutch?

How To Install a GoldTop Fan Clutch Kit

GoldTop Auto Lock - Preventing Fan Clutch Failures

GoldTop Fan Clutch Torque Test

| Weight | 25 lbs |

|---|

O.E. Equivalent, Fits most “Drive Master” applications.

Warranty 200,000 Miles / 24 Months.

| Kit Masters Part # | Replaces Manufacturer Part #(s) |

| 24-256 | 994347, 994373, 994375, 994377, 994379, 994381, 994900, 994985, 994995, 995035, 995054, 995054, 995530, 995534 |

Brand

Based on 0 reviews

0.0 overall

0

0

0

0

0

Be the first to review “24-256 Kit Masters 2-Speed Gold Top Fan Clutch Rebuild Kit for 2.56” pilot with 2 Pulley Bearings” Cancel reply

FAQs

–How much air pressure is required for a GoldTop to operate properly?

In order for a GoldTop fan clutch to operate properly, there must be between 90 – 120 psi of air pressure going into the fan clutch. This means the air pressure must be tested at the end of the air line, where it connects to the fan clutch. The compressor’s pressure gauge does not accurately show how much air pressure is actually entering the fan clutch.

NOTE: Bearing spacers always come in pairs – one for the inner race and one for the outer race. You should never install only one spacer.

–Do I need to put spacers between my pulley bearings?

There are several different pulley bearing configurations that you will find when rebuilding Horton® DriveMaster® fan clutches. Regardless of the number of bearings or the configuration of them, you will ALWAYS save and re-use any bearing spacers that come out of your original fan clutch. When installing bearing spacers, always place them between the bearings.

–How do I remove the “jack bolt” on the front of a DriveMaster® if it is stuck?

Quite often, the T-55 torx bolt, also known as the “jack bolt”, on the front of a DriveMaster® fan clutch will become stuck and you will not be able to loosen it. To solve this problem, first try applying heat to the bolt. If that does not work, use a 2 1/4” hole saw to cut the fan plate around the jack bolt. This will allow you to remove the fan plate and then access the friction screws. To see a demonstration, click here.

–Why won’t my GoldTop fit into the pulley?

If your GoldTop fan clutch assembly bottoms out, or doesn’t fit into the pulley, there are a couple of things to check:

1. Did you re-install the air chamber cap? If you re-install the air chamber cap (the coaster-shaped disc that was in front of the air cartridge) that you took out during disassembly, your GoldTop will not fit properly. The air chamber cap should be discarded during disassembly.

2. Are you installing the GoldTop on an International truck? Some Internationals have a modular fan clutch system that requires it to be installed on the truck one piece at a time. If you have one of these fan clutches, you will need an adapter, part number 24-4700.

–How do I know which pulley bearing configuration to use when installing a GoldTop fan clutch?

There are several different bearing configurations that you will find when rebuilding Horton® DriveMaster® fan clutches. To ensure that you install the proper replacement bearings and spacers, refer to this chart.

–My fan clutch is slightly damaged. Can I still rebuild it?

Before deciding if you will be able to rebuild your fan clutch, you will need to assess it. There are several points to inspect:

« Make sure the pulley is not chipped or damaged. If it is damaged enough to cause damage to the belt, the fan clutch will not be rebuildable.

« Make sure the bracket is not broken or cracked. If it is, the fan clutch will not be rebuildable.

« Check to see if the shaft is worn. A shaft that has been damaged or worn from the pulley bearings will result in repeat bearing failure.

« Check the inside of the pulley. Inspect to see if it is worn or damaged from the pulley bearings.

If the bracket, shaft and pulley are all in acceptable condition, you will be able to rebuild your fan clutch.

–Why won’t my GoldTop disengage?

First, check your air pressure right at the entry point of your fan clutch. You need a minimum of 90 psi, right at the entry point of your fan clutch, in order for it to operate correctly.

If you have more than 90 psi, right at the entry point of your fan clutch, and your fan clutch still won’t disengage, the Auto Lock feature on your fan clutch has kicked in.

–I have adequate air pressure, but my fan clutch still won’t disengage. Why?

If you have more than 90 psi, right at the entry point of your fan clutch, and your fan clutch still won’t disengage, the Auto Lock feature on your fan clutch has kicked in. When your friction material nears the end of its life, the Auto Lock feature fully engages your fan clutch to help you get to a service shop to get your fan clutch maintained, instead of leaving you stranded on the side of the road. Your fan clutch needs to be rebuilt or replaced.

–I just installed a GoldTop and my bearings failed within a couple days. What happened?

When you installed your pulley bearings, you most likely did not install your inner race bearing spacer, which should always be installed along with the outside race bearing spacer. If you do not install the inner race bearing spacer, when the 2” bearing nut is torqued down on the shaft, it pre-loads the inner race of the bearings causing them to prematurely fail.

–My fan clutch won’t disengage and is leaking air through the back of the bracket. What happened?

The air cartridge is not mating correctly against the bottom of the GoldTop. Inspect the carbon on the air cartridge. Replace your air cartridge if needed.

–Why won’t my GoldTop engage?

When your fan clutch won’t engage, this usually means that your GoldTop is out of friction. To test this, shut off your truck and try to spin your fan blade. If you can spin your fan blade, then you have no friction left and your fan clutch assembly needs to be rebuilt or replaced. If your fan blade does not spin, your fan clutch is properly engaged. GoldTop fan clutches engage when there is no air reaching the fan clutch.

–What is the difference between a 24-256 and a 24-256-1?

The difference between GoldTop part numbers 24-256 and 24-256-1 is the bearings. Part number 24-256 contains two 6209 bearings, while part number 24-256-1 contains one 3209 bearing. These bearings are not interchangeable.

–My truck is mainly used for long haul loads and I’m rarely stuck in traffic. Does it make sense for me to upgrade to a GoldTop 2-speed fan clutch?

Although a GoldTop 2-Speed fan clutch will provide the greatest benefit to vocational vehicles that have a high percentage of idle time, it also provides benefits to over-the-road trucks. These benefits include improved fuel economy, less noise and longer fan clutch life.

–Can I convert a single-speed Horton® DriveMaster® fan clutch into a 2-speed?

Yes. Horton® DriveMaster® fan clutches can be rebuilt using either a single-speed GoldTop or a 2-Speed GoldTop fan clutch rebuild kit. The installation process is identical.

–Do I need to change my engine fan when converting to a 2-Speed GoldTop?

No. A 2-Speed GoldTop has an exclusive interchangeable pilot, meaning that it can handle both 2.56” AND 5” fan pilots. There is no need to change your engine fan.

There are no reviews yet.